HEAT EXCHANGER

Introduction

Heat transfer is perhaps the most important as well

as most applied process in chemical and petrochemical plants. The economics of

plant operation often are controlled by the effectiveness of the utilization

and recovery of heat .The word exchanger applied to all type of equipment in

which heat is exchange but is often specifically to denote equipment in which

heat is exchange between two process streams. A heat exchanger is a piece of

equipment that continually transfers heat from one medium to another, without

mixing the process fluids. Heat exchangers are used to pre heat the feed for

the Stripper.

Significance in Process

Basic purpose of heat

exchanger is to heat the waste oil to its bubble point temperature (134oC)

from 25oC, so it can be used in flash distillation column

CLASSIFICATION OF HEAT EXCHANGER

In general

industrial heat exchangers are classified according to there: Construction

1.

Transfer

processes

2.

Degrees of

surface compactness

3.

Flow

arrangements

4.

Pass arrangements

5.

Phase of the

process fluid

6. Heat transfer mechanism

Classification according to Construction

According

to construction heat exchangers are:

1)

Tubular heat

exchanger (double pipe, shall and tube, coiled tube)

2)

Plate heat

exchanger (gas kited, spiral, plate coil, lamella)

3)

Extended surface exchangers (tube fin, plate fin)

4)

Regenerators

(fixed matrix, rotary)

Classification according to

Transfer Process

These

classifications are:

1.

Indirect Contact

(double pipe, shall and tube, coiled tube)

2.

Direct contact

(cooling towers)

Classification according to

Surface Compactness

A compact heat

exchanger incorporates a heat transfer surface having a high area density,

which is the ratio of heat transfer area (A) to its volume (V) it is somewhat 700

m2/m3. They can often achieve higher thermal

effectiveness than shall and tube exchangers. (95% vs. 60-80% for STHE) which

makes them particularly useful in energy intensive industries.

Classification according to Flow Arrangement

The basic flow

arrangements in a heat exchanger are

1. Parallel flow

2. Counter flow

3.

Cross flow

The choice of a particular flow arrangement is

dependent upon the required exchanger effectiveness, fluid flow paths,

packaging envelope, allow able thermal stress, temperature levels etc.

Classification according to Pass Arrangement

A fluid is

considered to have made one pass if it flows through a section of heat

exchanger through its full length once. There are either single pass or multi

pass , in a multi pass arrangement the fluid is reversed and flows through the

flow length two or more times. The multi pass arrangements are possible with

compact shall and tube and plate exchangers.

Classification according to Phase of Fluid

These

classifications is made according to the phase of the fluid I-e gas-gas,

1. liquid-liquid

2. Gas-liquid

Heat Exchanger Selection

Criteria

When selecting a heat exchanger for a given

duty the following points must be considered

1.

Material of

construction

2.

Operating

pressure and temperature

3.

Flow rates

4.

Flow

arrangements

5.

Performance parameters--thermal

effectiveness and pressure drops

6.

Fouling

tendencies

7.

Types and phases

of fluids

8.

Maintenance,

inspection, cleaning, extension, and repair possibilities

9.

Overall economy

10. Fabrication technique

11. Intended applications

Types of Heat

Exchanger

1.

Double pipe

2.

Shell and tube

3.

Spiral type

4.

Plate and frame

5.

Compact heat exchanger

Types of shell & tube heat exchanger

1.

Fixed tube

2.

U tube

3.

floating head

Advantages of Shell and Tube Exchanger

1.

It is used for

high heat transfer duties.

2.

It occupies less

space.

3.

Its compactness

is more.

4.

Its maintenance

is easy.

5.

It can be

fabricated with any type of material depend up fluid properties.

Typical Shell-and-Tube Heat Exchanger

FLUID

ALLOCATION

1-Shell

side fluid selection (Reactor Effluent):

Ø High viscosity fluid.

Ø Fluid which exhibit low heat transfer coefficient.

2-Tube

side fluid selection (steam):

Ø Fluid at high pressure.

Ø Corrosive fluid.

Ø Fluid having high heat transfer coefficient.

GEOMETRICAL

DESIGN

1. SHELL:

i.

Shell type

ii.

No. of shell

iii. Shell id.

2. TUBES:

i.

Outer dia.

ii.

Wall thickness

iii.

Tube pitch

iv. No. of tubes

3. BAFFLES

i.

Baffle type

ii.

Baffle cut

iii.

Orientation

iv.

No. of cross

passes

SHELL SELECTION

Shell

diameter

Range

is 200mm to 2500mm

Shell orientation

i.

Horizontal

ii.

Vertical

I have selected horizontal because,

Ø Frequently used

Ø Easy maintenance

Ø Economical

TUBE SELECTION

Type:

Plane

tube

Ø Commonly used

Ø Readily available

Ø Wide range of wall thickness

Tube

OD and wall thickness:

0.0195m, 10 BWG

Tube length:

Standard length are used

(2.44,3.66,4.88 m)

Tube

effective length:

For floating head

Le=L-2Ts

L= length

Ts= tube sheet

thickness

for

Ds<500mm ; Ts=50mm

Tube pattern:

i.

Triangular pitch

ii.

Rotated

triangular

iii.

Square

iv.

Rotated square

I have selected triangular pitch because

Ø Large

no of tubes can be accommodated

Ø It

provides large surface area

Ø High

heat transfer

Tube pitch:

Standard

way is 1.25times or more than this outside diameter

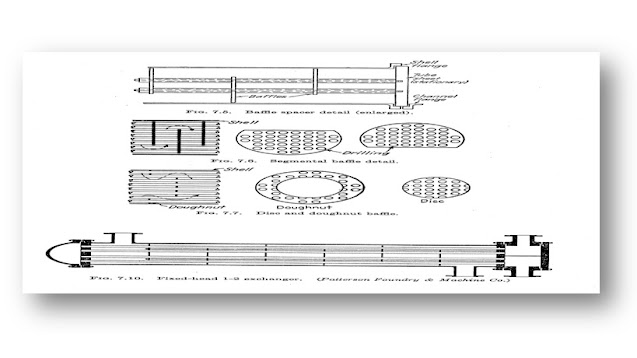

BAFFLES

i.

Segmental baffles

ii.

Disc and doughnut

iii.

Orifice baffles

Segmental baffles:

Cross

baffles are provided in shell and tube heat exchanger in order to force the

shell side fluid to flow across the tube bundles and to support tube bundles

Types:

i.

Single segmental baffle

ii.

Double segmental

iii.

Triple segmental

Single

segmental baffles are used unless there is no

pressure drop limitation

Baffle cut

For

segmental and single phase service 25 percnt recommended.

Orientation:

i.

Vertical

cut

ii.

Horizontal cut

iii.

Single phase with solids

Baffle Spacing:

Normally

0.2-1 shell ID

Minimum baffle spacing should not be less than the

1/5 ID of shell or 50mm

Design

procedure for shell-and-tube heat exchangers:

|

Reactor Effluent |

Steam |

||

|

Flow rate |

3116 (Kg/hr) |

Flow rate |

3086(Kg/hr) |

|

Inlet Temperature |

220 oC |

Inlet Temperature |

370oC |

|

Outlet Temperature |

335oC |

Outlet Temperature |

370oC |

|

Pressure |

40 atm |

Pressure |

21 atm. |

|

CP |

3.99 (Kj/Kg.oC) |

Latent heat |

452.6 (Kj/Kg. ) |

Design of heat exchanger

DESIGN

STEPS

1-HEAT LOAD:

used oil:

Q = m cp (tc,out

– tc,in)

=3116*3.99*(335-220)

=388

kj/sec

steam:

M steam=q/λ

AT 370 oC

;

λ=452.6Kj/kg

M steam

=406.7e3/2041

=0.85kg/sec

m=mass flow rate of oil

m=mass flow rate of steam

λ=latent

heat

Calculation of

LMTD:

=79 oC

ASSUME:

Ud=220 W/m2 c

A=Q/Ud.LMTD

=70.3 m2

OD=19.5mm

BWG=10

0.024 m triangular pitch

L=length=4.88 m

Le=L-2Ts (Ts=50mm for ID<500mm)

=4.78 m

Area of 1

tube, At,=πDoL =0.31m

No of tubes,Nt=Ao/At

=150

For 2 tube passes,no of tubes=75

|

HOT

FLUID(tube side) 4-FLOW AREA: at=Nt*π/4*Di2

=0.012m2 5 vol. flow rate=W/ρ 7-MASS VELOCITY: Gt=W/at

=71.58Kg/m2.sec 8-at Tavg=370 oC μ=9.8e-5 pa.sec 9-Di=0.01483 m 10-Re=D*Gt/ μ

=10832 11- hio=15000W/m2.k

|

COLD

FLUID(Reactor Effluent) 4-FLOW AREA: as=(Pt-Do) *Ds*Lb/Pt =0.07m2 5- vol flow rate=w/ρ =3.3e-03 6-shell side vel=vol flow/as =0.5m/sec 7-MASS VELOCITY: Gs=W/as

=123.7kg/m2.sec 8- Tavg

=277.5oC μ=3.89e-4 pa.sec De=4(Pt2

–(π/4) do2)/πdo

=0.014m 10- Re=De*Gs/

μ =4452 9- Jh=4.5e-03 10- Ta=277.5oC k=0.142W/m.

oC (Cp

μ/k)⅓ = 10.7

11- ho =Jh.k/DePr(Cp

μ/k)⅓. ho=466

W/m2.k |

1/Uo=1/ho+1/hod+(do*ln(do/di))/(2Kw)+(do/di)*hid+(do/di*hi

U0=247 W/m2 oC

PRESSURE DROP

|

TUBE: 1- Re =

10832 2- Jf =2.3e-03 ΔPt=Np[8Jf(L/di))*(µ/µw)0.14+2.5]*ρ*ut2/2 =13

KPa |

SHELL: 1- Re= 4452 Jf

=6e-02 ΔPs=8*Jf(Ds/de)*(L/Lb)(ρ*us2

/2) =42.2 KPa |

SPECIFICATION

SHEET

|

Equipment |

1-2 pass shell

& tube heat exchanger |

|

Shell passes |

1 |

|

Tube passes |

2 |

|

Heat transfer area |

70.3m2 |

|

Shell diameter |

400 mm |

|

Tube pitch |

0.024 m |

|

No of tubes |

150 |

|

Type of tube uses |

10 BWG |

|

NO 0f baffles |

3 |

|

Tube outer

diameter |

0.0195 m |

|

Tube inner

diameter |

0.01485 m |

|

Pressure drop

on tube side |

13 KPa |

|

Pressure drop

on shell side |

42 KPa |

0 comments:

Post a Comment